Heavy-duty crates are developed for a variety of needs and industries. Many crates are needed for only a single use. The product is crated and is designed to be adequately protected for the journey to its destination. Once there, the wood from the crate is repurposed for building or fuel.

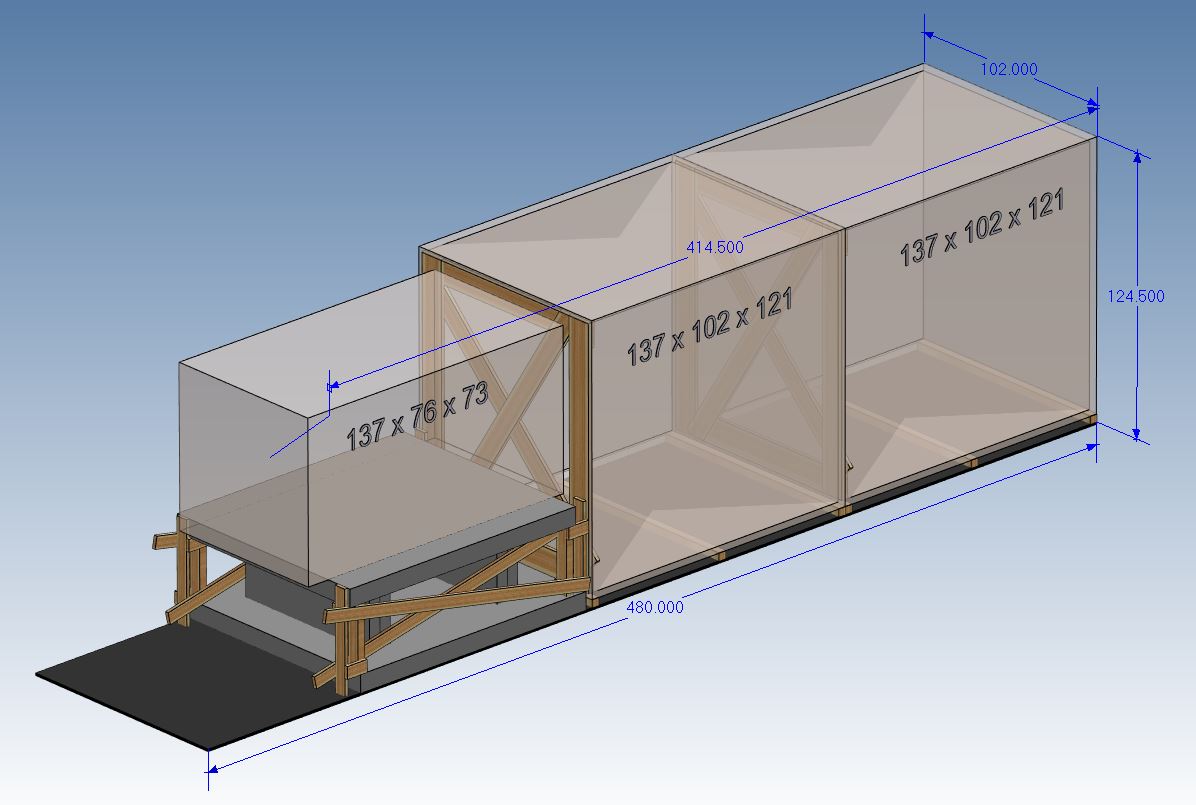

Heavy Duty solutions are often needed when a product is either large or heavy. Either of these situations requires planning and structural support. When the item is both large AND heavy, then we must plan accordingly to ensure your product is delivered to your client intact and ready for use. Our engineering team uses their knowledge, and the latest CAD software to design a solution that meets the requirements at the most cost-effective price point.

Other crates are designed with additional structural integrity so that the crate can be re-used for 5, 10, or more round trips. Our clients simply define what the crate must minimally deliver, and our engineer will build heavy-duty crates for that need. In each case, our goal is to protect your product throughout the delivery at the most cost-effective price point.

Reusable Crates

A reusable crate is needed whenever a product is going to be moved from place to place for additional components or full rebuilds.

Crating Solutions for the Power-Generation Industry

One such need is with power-generating turbines. These turbines are constantly moving. Therefore, they must be replaced periodically for the power generating station to perform at maximum efficiency. Companies that build these turbines will utilize many parts from the old equipment. The power generating station will replace the unit, and return the old turbine. Our client will then rebuild the turbine, replacing the pieces that have worn over time. Our client is then able to utilize the housing components that have a longer useful lifespan.

Click any image above to enlarge

Custom Reusable Shipping Cartons for Aviation

Another common need for a product to be shipped multiple times during production is in aviation. The completed aircraft is worth millions of dollars. The production of such aircraft involves multiple countries or facilities contributing to the completed product. Consider the series of pictures below which illustrates how we were able to protect the tail of an Airbus helicopter. We incorporated a sled to make it easy to move in and out of the crate. The shell keeps it protected throughout the production life cycle. This particular crate was reused more than 10 times during its life cycle.

Click on any picture to enlarge and engage the slideshow.

Moisture-Proof Shipping Solutions

Overseas shipping is typically done via cargo ships, which means goods have to be protected from the perils of the sea. When ships pitch and roll during their journey, goods can be exposed to saltwater. It’s also common for crates to remain on cargo docks for extended periods. Therefore your product might be exposed to high levels of humidity depending on the destination.

Our vapor barrier bagging is a perfect solution for this situation and will protect your component from the corrosive nature of saltwater and humidity. This can also be critical with air shipments as products are exposed to extreme changes in temperature and altitude. With these changes, equipment is prone to excessive condensation, and our vapor barrier bagging system will protect it.