Do You Have A Custom Crating Need for Shipping or Storage?

QR Code for Video

Scan to Share Video from Your Phone

Building on a nearly 23-year success story, Freight Crafters and RSI Crating and Packaging are now DFW Crating and Packaging. Freight Crafters, Inc. was established in 2001, serving clients throughout Dallas – Fort Worth metroplex and all over the world. In 2019, we acquired RSI, Inc. – a company that had been providing similar services to its customers for over 30 years. By taking advantage of complementary core competencies, DFW Crating and Packaging gained a firm leadership position in the marketplace. We can proudly say that DFW Crating and Packaging has the experience, expertise, and capacity for creating ALL types of custom packaging solutions for any industry, no matter the complexity.

Currently, we serve companies specializing in aerospace, energy generation, oil and gas, medical, defense, advertising, furniture building, high-tech, 3-D printing, food processing, automotive, mining equipment, heavy industrial machinery, etc. Our company’s custom-engineered crating solutions will protect your products whether they are shipped via truck, train, sea, air, or if you need a long-term storage solution. As we developed our core staff, we purposefully sought out people with established experience, and they have remained with us for years. Some team members have been building custom crates and packaging solutions for over 30 years!

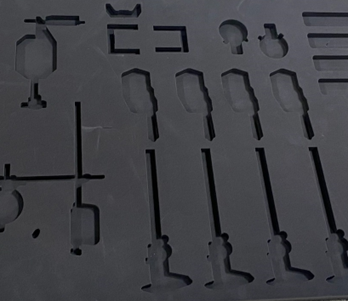

Images on this page demonstrate only a small sample of the multitude of industries we serve. These pictures were chosen with a specific purpose to illustrate the complexity of the engineering challenges we solve. Components for aviation, automotive, offshore drilling, turbine power generation, and other manufacturing applications often cost hundreds of thousands to produce, while complex instruments may cost millions. DFW Crating and Packaging has the expertise to prepare these items for shipment, which means a healthy bottom line for your business.

Our packaging solutions and custom crates are designed for your product and built with safety in mind. Our engineers study each product we crate to build in safeguards against damage during transportation: center of gravity movement, moisture barriers (if needed), minimization of crate bowing, enhancements for reusability, show crates, etc. We use advanced CAD software in our design process that allows us to demonstrate exactly how your component will be packaged and supported throughout the shipping process. Moreover, we digitally store all crate and pallet drawings to ensure precise repeatability of the process in the future. Our clients can always rest assured that we are providing the best possible protection for their invaluable assets!

DFW Crating and Packaging uses ISO9000 as its guide during the implementation of its engineering, production, and quality assurance processes. In addition, while serving our overseas clients, we can meet a majority of the international crate-building and packaging standards.

Only ISPM-15 Certified materials are used in the company’s facilities; hence, each crate or pallet will have a unique stamp verifying compliance. As a condition of obtaining the stamp, DFW Crating and Packaging is audited monthly by a third party. This independent auditor scrutinizes purchasing documentation, storage processes, and lumber quality to validate compliance.

Our Core Values

We consider capability, credibility, and reliability to be the cornerstones of our core values. With care and pride, we built a company that provides world-class services to our customers globally. We assembled a highly-skilled team, and, with the help of the latest technology, we are ready to fulfill all your crating and packaging needs at a competitive price.

Our Promise

No matter the size and complexity of your crating or packaging needs, DFW Crating and Packaging will provide quality on-time services, within the estimated budget, and to your complete satisfaction.

Our Commitment to the Customer

How can I define world-class customer service? Customer service is all about consistently exceeding customers’ expectations – relentless communication during project assessment, making the design surpass customer anticipation, delivering on time, project execution within budget, continuous process improvement, no excuses made, and zero unresolved challenges.

– Mark Mathews, Founder of DFW Crating and Packaging

Our Clients Say

“Best service and very knowledgeable staff if you need it crated and done right these are the guys to use”